At I2T, we provide world-wide automation solutions from semi-automated to complete turnkey systems. We can provide electrical/mechanical automation systems for discrete part manufacturing, machine tending, assembly machines, packaging, inspection systems, web converting, pick-and-place, sorting, etc. We have developed systems for the automotive, aerospace, tire and rubber, glass, food, and medical markets. In our development we utilize the latest software and design tools such as SolidWorks, AutoCAD, Microsoft .NET, along with the development software from major control manufactures such as Aerotech, FANUC CNC & Robotics, Rockwell, Siemens, Omron, Inductive Automation, and others. The technologies that we use allow these systems to be incorporated into your plant wide MRP/MES systems. We can provide complete networked solutions from islands of automation to your entire plant for tracking production, quality, and downtime. As part of a network solution, we can also provide Overall Equipment Effectiveness (OEE) applications as part of the automation to track the downtime, productivity, and quality of the manufacturing process.

Every project starts with a site evaluation with your management, engineering, and process control staff to determine what is needed to efficiently produce the best quality products for your manufacturing process. A Hardware and Software Design Specification is developed and reviewed with your manufacturing team to ensure all the design criteria for quality, cycle time, operability, reporting, etc. will be met. From these specifications bills of material, design models, fabrication drawings, electrical drawings, Factory Acceptance Test procedures, and operator/management interface designs will be produced. Upon approval, these designs and specifications will be used by our mechanical/electrical shops for fabricating the components, assemblies, and controls for the complete automation system. Shop visits and design reviews are encouraged throughout the whole process to ensure a timely installation and flawless production startup. Upon completion and delivery of the automation equipment, I2T can provide complete installation or installation support utilizing your plant’s trade personnel. Once startup is complete operator, maintenance, and engineering training are provided to ensure proper handover of the complete system to your personnel.

To find out more, please contact us directly to learn how we can provide you with successful automation solutions that you can depend on.

I2T has been providing complete motion control solutions since 1990 from simple point-to-point single axis applications to complex multi axis profiles requiring complex kinematic equations running in real time. Our competent engineering staff has the knowledge and experience to provide our customers with solutions for enhancing the function of existing systems or designing high performance motion specific automation meeting or exceeding their criteria. We can provide solutions incorporating PC, PLC, CNC or proprietary based platforms. Some of the motion control suppliers that we have integrated on past projects include: Aerotech, Rockwell, Siemens, Omron, Yaskawa, FANUC, Schneider Electric, Kollmorgen, Delta Tau, and Galil.

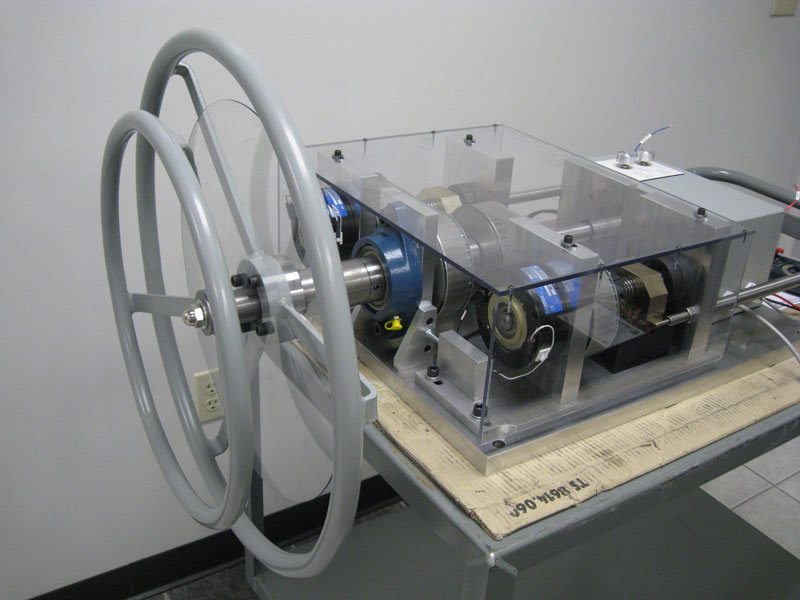

We can upgrade your process to the latest technology by retrofitting your old obsolete motion controller, drives and motors with the latest offering from various hardware suppliers. Even gears, line shafting, and cam boxes can be eliminated with the adaptation of servo motors which can electronically provide you the same or better performance without the maintenance nightmare. These new systems can then be integrated into plant wide networks to provide productivity reports, downtime and maintenance.

Retrofitting motion control systems is one of our specialties; we extend the life of our customers’ machines with current control systems, designed to provide older machines with enhanced flexibility and efficiencies of new equipment. We’ve worked with a number of high profile Fortune 500 companies who put their trust in us for the refurbishment of various machines and systems, integrating cutting edge controls and user interfaces that provide peak performance and up-to-date standards.

Whether working on old or new systems, our motion control capabilities cover a broad spectrum. We repair and build simple or complex multi-axis motion control systems using either 100% digital drives or a combination of digital and analog. Software development for motion control technologies is also available; we modify existing software programs as well as create custom-designed software to suit our customers’ exact specifications. Our engineers provide complete forward and reverse kinematic studies for developing coordinate transformation equations for complex mechanical systems. Working closely with our customers, we create custom interfaces that give operators intuitive control over the most complex processes.

Using our wide breadth of knowledge and experience, we seamlessly integrate motion systems into automation projects on-site at the customer’s plant with minimal disruption to operations. Full installation, start-up, and training services are available as well, providing clients with a true turnkey solution. Our motion control products are used for many complex systems, including custom robotics, inspection systems, grinders, milling machines, lathes, roll grinders, packaging systems, and many others.

For more information about our motion control capabilities, contact us directly.