I2T has been a major force in automation and motion control for over 30 years. Our name has become synonymous with high quality, high tech solutions for a wide range of industrial systems. This tradition is exemplified by our superior quality retrofitting services. We specialize in upgrading the obsolete control equipment of existing mechanical operations into modern, state-of-the-art systems. A broad range of retrofitting capabilities is available. They include custom machine building, programing, documentation, design, prototyping, training, field support, and consulting.

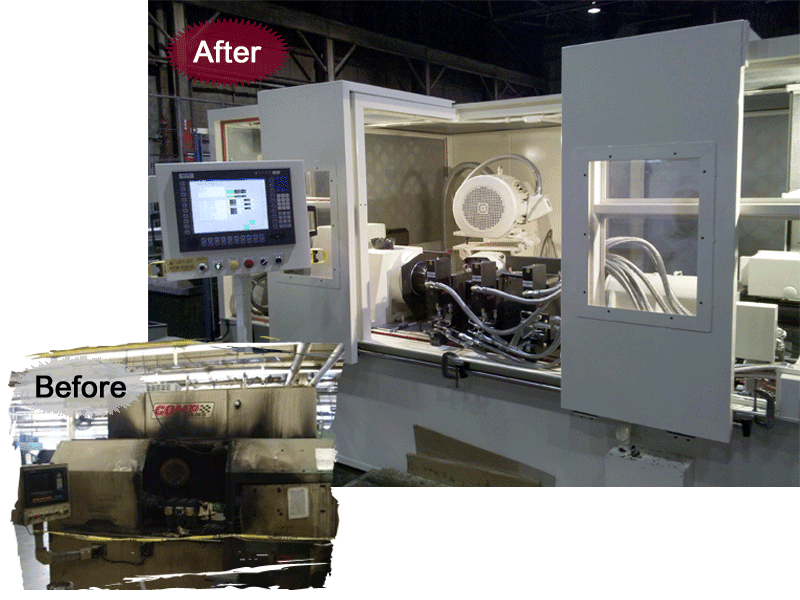

Equipment and mechanical components that are close to or at the end of their service life are always at risk of causing unexpected down time or delays to production. The increased likelihood of inaccuracies and, in some cases, outright system failure can result in serious financial ramifications. Our retrofitting services improve machine functionality and reliability by finding and removing older components, such as gearing, line shaft, and CAMs. These elements are replaced with advanced electrical equipment that uses servo motion control, extending the life of the system and reducing the need for future maintenance. Our retrofitting and replacement services have served a broad variety of applications, including machine tool, glass handling, conveyors, presses, tire and rubber machines, progressive press transfer, and robotic pick and place tools.

Our retrofitting services allow our customers to keep the best of both worlds. We reuse the existing part programs and process routines that are fully functioning, thereby minimizing debugging and operator training which would be unnecessary for personnel who are familiar with the existing equipment. While these programs are kept, modern equipment control brings new services such as data mining and networking to old equipment. This provides a wealth of information for preventative maintenance, ultimately raising machine throughput to the highest levels possible.

Our technological improvements cover a number of other areas, including better logging, diagnostics, and other tools for the best understanding and maintenance of equipment. Retrofitting is available for a broad array of systems that include grinders, milling machines, part-handling gantries, lathes, roll grinders, punch presses, and CNC machines. Our services employ some of the biggest names in control system technology, regularly using products from Siemens, Allen Bradley, FANUC, Omron, Modicon, Mitsubishi, and others.

We have worked with a variety of Fortune 500 companies to refurbish and retrofit their machines. Our work makes older machines easier to use and helps improve performance in almost every case. To find out more about our retrofitting services, contact us directly.