At I2T, we partner with the most some of the most well-known suppliers in the industry to provide our customers with the most advanced machine vision equipment available. Modern vision systems are designed to deliver improved image quality, and are ideal for image restoration, picture coding, and image interpretation. Whenever an industrial application needs identification, guidance, or measurement, machine vision is a widely-used choice.

Our team of machine vision experts have years of experience in developing vision technology solutions for a wide variety of applications. Our general capabilities cover an expansive range, some of which include full design, development, fabrication, programming, and lighting evaluation. Custom machine vision solutions from I2T are used in conjunction with a wide variety of industrial equipment, processes, and software. We work with projects that employ CNC mills, grinders, quality control, and inspections.

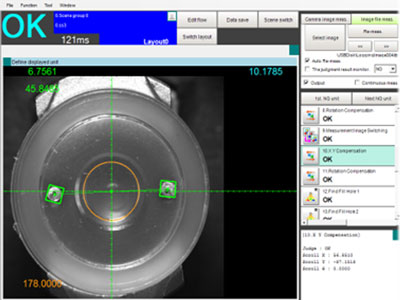

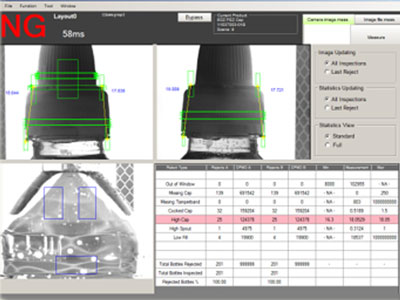

We have employed machine vision technology in many specific projects to improve efficiency and productivity. We have used this method in the development of inspection stations in order to provide precise, repeatable part measurement for quality control. In another project, we integrated vision systems in order to locate parts in a fixture that were arbitrarily positioned in order to apply rotation offsets and translation to the motion process. Custom machine vision was also used for high-speed line inspection and label readers to track and reject products in a large automation line.

These examples are just a snapshot of the diverse array of systems where we deployed advanced vision systems to solve complex production problems. In each instance, our expertise and comprehensive planning and execution delivered a robust solution.

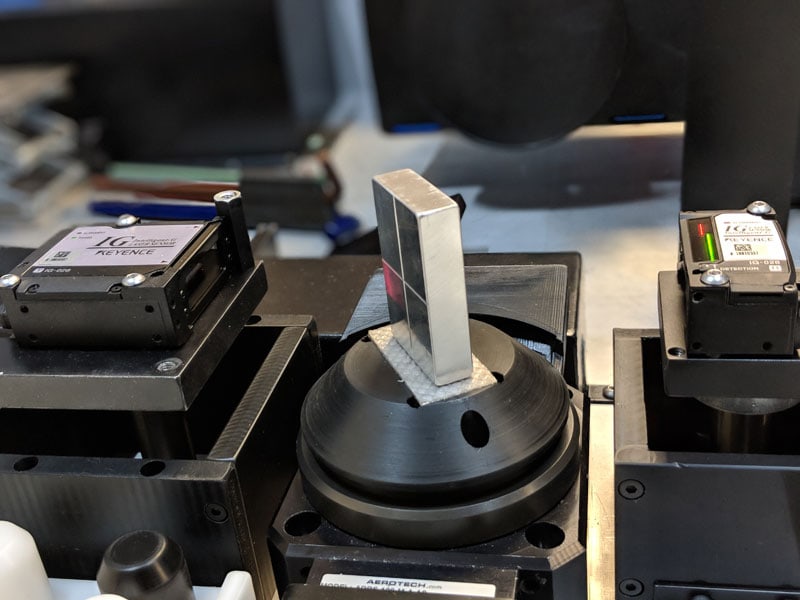

With each engagement, we employ a development process that includes the staging of parts in our lab in order to determine lens, light, and camera requirements for processes before installation occurs. Vision and integration programming are also available, as well as debugging, dry-run testing, set-up, and engineering analysis. In addition to part handling and inspection, our custom machine vision solutions have been employed in palletizing, packaging, and unpacking applications.

The industries that benefit from machine vision cover a broad spectrum, and include aerospace, automotive, electrical, food processing, medical, pharmaceutical, oil, gas, and petroleum. To learn more about our machine vision technology and how it can benefit your operations, contact us directly.