As a full service provider of automation and control systems, customers across a broad range of industries rely on us to provide solutions tailored to their specific needs. In this project, we were tasked with the development of complex and high-precision vision inspection systems for one of our existing customers, who knew we could deliver the correct solution. At Integrated Industrial Technologies, Inc., our ability to provide complete systems allows our customers to have all their needs met by a single vendor.

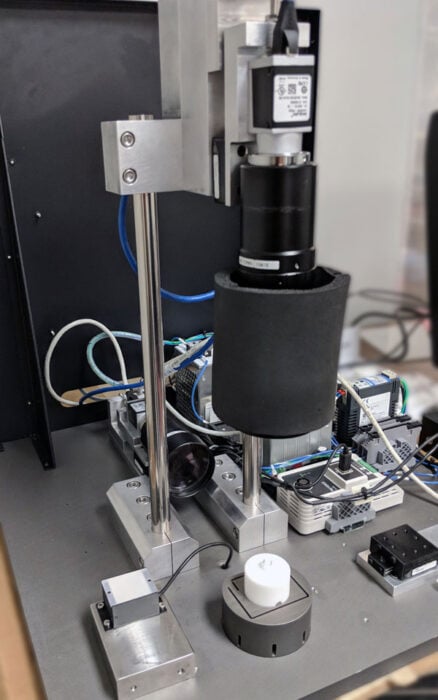

The machine vision inspection station shown here is a typical example of a complete ground up project that will fit in seamlessly with the larger needs of a facility. Customer specifications for the machine included the ability to inspect parts with 10 µm accuracy, integration with an existing software library, and to provide highly accurate recording of all test data. The greatest challenge we faced with this project was the difficulty of getting the vision systems to accurately and consistently detect parts that were clear. This was compounded by the tight delivery date.

The completed system was developed with VST lights and lenses, two Basler cameras, the Halcon vision library, and .NET programming. We achieved the part measurement accuracy to ± 10 microns and ± 0.25 degrees. This project represents a complete end-to-end effort that included engineering, design, and fabrication of the system, including all electrical, mechanical, and vision aspects. We also provided complete installation and comprehensive debugging, and worked with the customer to develop all of the associated documentation such as manuals and test drawings. Complete factory acceptance testing was performed prior to shipping, and once installed, customer validation testing was held without incident. This system also met a number of very stringent standards for medical parts manufacturing. In operation, the system takes a number of individual measurements on each part and records the data to the customer’s database for statistical analysis and audit trail history.

To learn more about this project, contact us directly.